|

Qingdao Megatro Mechanical and Electrical Equipment Co., Ltd

|

Gold Index: 3476

You are here: home > MEGATRO suspension tower and accessories

MEGATRO suspension tower and accessories

| Price: | 1100.0 USD |

| Payment Terms: | T/T,L/C, |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

MGP-ST001

Production Capacity:

50000 tons/year

Delivery Date:

30DAYS

Means of Transport:

Ocean,

Packing:

both parties discuss before...

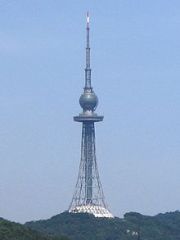

MEGATRO suspension tower and accessories

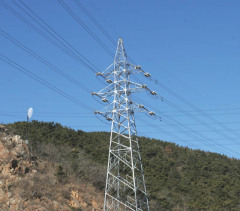

In an electric power transmission line, a suspension tower is where the conductors are simply suspended from the tower, the mechanical tension being the same on each side.In this case, the tower is supposed to carry a downward force, and a lateral force, but not a longitudinal force.

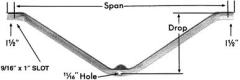

These may have, for each conductor, an insulator string hanging down from the tower, or two strings making a "V" shape. In either case, sometimes several insulator strings are used in parallel to give higher mechanical strength.These are used where a transmission line continues in a straight line, or turns through a small angle. In other cases, a tension tower (C or D Towers) is used.

MEGATRO fabricates every structure suspension tower by solid steel legs and angle iron cross members & pipes. Structures can reach heights up to 200 meter. MEGATRO is one of the few manufactures who assemble a face of every tower section. This attention to quality may not be the cheapest process but it does insure every tower meets our high standards of quality. And it helps to reduce on-site construction cost due to mismatched assemblies.

After fabrication all suspension tower are delivered to the galvanizing facility to be Hot Dip Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers.

MEGATRO's suspension tower systems can accommodate a variety of cross-arm. MEGATRO also offers a wide variety of accessories and mounts.

Related Search

Suspension Parts

Air Suspension

Suspension System

Suspension Insulator

Suspension Strut

Suspension Arm

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Qingdao Megatro Mechanical and Electrical Equipment Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Qingdao

Province/State: Shandong

Country/Region: China (Mainland)

.gif)