|

Qingdao Megatro Mechanical and Electrical Equipment Co., Ltd

|

Gold Index: 3476

You are here: home > MEGATRO termination tower and accessories

MEGATRO termination tower and accessories

| Price: | 1100.0 USD |

| Payment Terms: | T/T,L/C, |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

MGP-TT015

Production Capacity:

50000 tons/year

Delivery Date:

30DAYS

Means of Transport:

Ocean,

Packing:

both parties discuss before...

MEGATRO termination tower and accessories

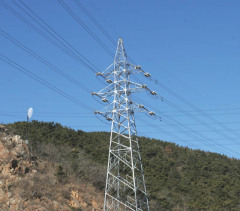

A special kind of a dead-end tower is a termination pylon. Also called a terminal tower. It is used when the overhead power line terminates, and is connected to substation equipment, or transitions to underground cable.

For crossings of large bodies of water, wide freeways, or valleys, where the span width of the conductors is very long, specific constructions must be used to achieve a wider distance between the conductors, mostly to prevent short-circuits which may occur when conductors come in contact with one another due to wind or other interferences. Therefore, termination tower was used at this condition, these towers may be built as H-frame towers, or may have each conductor placed on a single tower or mast. In every case, these towers are built more stably than most of the other towers used, as the wide span between towers means that much greater forces are placed on these towers.

MEGATRO fabricates every structure termination tower by solid steel legs and angle iron cross members & pipes. Structures can reach heights up to 200 meter. MEGATRO is one of the few manufactures who assemble a face of every tower section. This attention to quality may not be the cheapest process but it does insure every tower meets our high standards of quality. And it helps to reduce on-site construction cost due to mismatched assemblies.

After fabrication all termination tower are delivered to the galvanizing facility to be Hot Dip Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers.

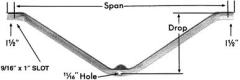

MEGATRO's termination tower systems can accommodate a variety of cross-arm. MEGATRO also offers a wide variety of accessories and mounts.

Availability size: Based on the customer's requirements.

Material: Chinese material or as per clients requirement

Related Search

Termination Box

Termination Kit

Fiber Optic Termination Box

Wall Termination Box

Fiber Termination Box

Optic Termination Box

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Qingdao Megatro Mechanical and Electrical Equipment Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Qingdao

Province/State: Shandong

Country/Region: China (Mainland)

.gif)